What sets BLUE BOX™ apart

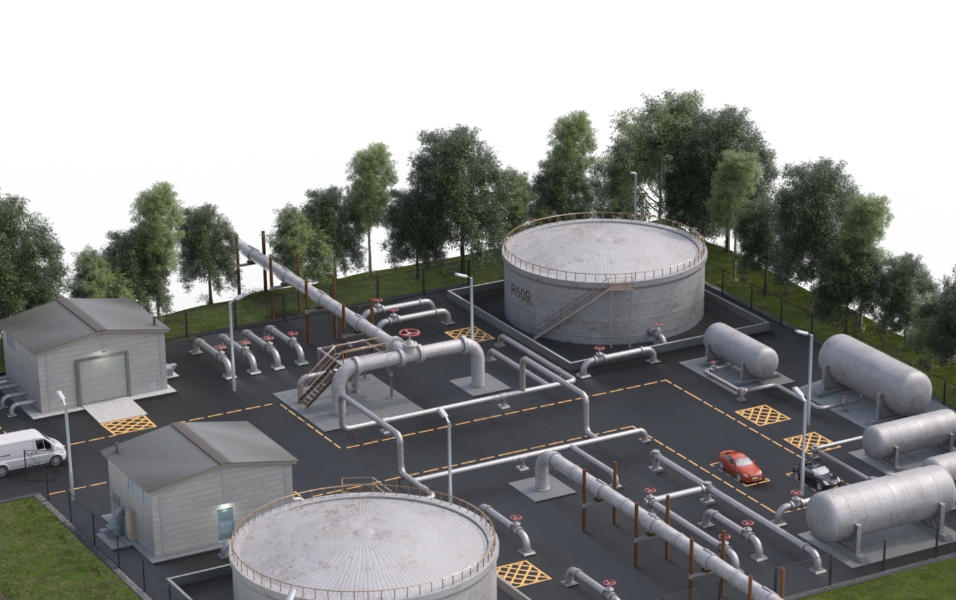

Operators of critical pump assets are faced with growing operational challenges, while at the same time the increase in the amount of data requires an advanced approach to make this data actionable.

Secure

State-of-the-art IoT technology

Smart

Artificial Intelligence (AI) based modeling

Supported

Deep expertise in pump technology